Using sensor data to optimize your greenhouse/grow operation

Whether you are a grow operator supplying fresh herbs and produce to grocery stores, a flower grower, or a medical cannabis grower, the feedback we hear back most frequently from growers is that the ability to create and maintain the ideal environment for the specific plant in the grow operation at is key to making the operational fully profitable.

Managing a grow operation manually is a time-consuming and labor-intensive process and reacting to problems can sometimes be challenging. Two of the largest costs of running an indoor grow operation are labor and energy.

The ability to reduce the overall growth cycle has a direct reduction of labor costs and energy consumption in the operation is critical to the overall success and profitability of the business.

Commercial greenhouses and growers are especially challenged to improve production efficiencies in every part of the operation. Competition is stiff, and forward-thinking growers must continually find new ways to improve to remain competitive in their market.

Reducing the energy costs of running the operation (water, lighting, heating, cooling) and automating regulatory inventory control systems (METRC) can go a long way toward improving the profitability of the overall growth operation.

Over the past few years, the costs of the technology to capture key grow room/greenhouse data points have lowered.

In addition, environmental parameters including lighting, heating, cooling, ventilation, and other such systems have been lowered enough to allow for highly automated, data-driven agricultural control solutions to be developed.

And at a cost that is palatable to the operation and that has a good return on investment (ROI).

This Business White Paper will describe the various systems and solutions that make up the overall Clarity IOT Agricultural Control System (ACS).

In this White Paper, we will show you how our sensors can be used to help optimize and streamline many of the labor and energy-intensive activities in the current operation.

In this paper, you will learn how the Clarity ACS solution can be used to help monitor and control the various environmental systems in the current production operation.

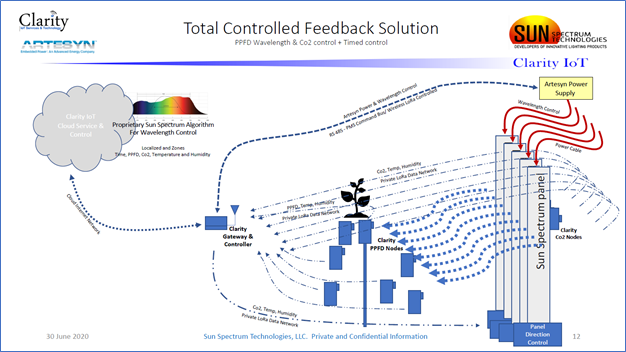

A Total Controlled Feedback Solution

At the heart of the Clarity ACS (Agricultural Control System) solution is a complete Cloud-based “internet-enabled” sensors and technologies that can be easily installed and deployed in the operation.

These sensors feed a continuous stream of environmental data (typically captured every 5-minutes) of the current value of the sensor being monitored.

The Clarity system tracks lighting conditions, PAR (PPFD) values, temperature, humidity, and CO2 levels in the environment.

All data captured by the system is stored in the cloud forever which means that as the system continues to be monitored, problems can be identified and addressed before issues arise.

At Clarity IOT…It is all about the data.

It’s all about the data because the data stored in the Clarity IOT cloud database can trigger the Clarity ACS system,

The Clarity ACS System reacts based on the data captured by the sensors in the system and cross-referenced against the configuration parameters set in the software by the head/lead grower.

The system can be configured to react and make changes to the environment based on parameters captured in the Cloud software.

Environmental systems can be controlled to optimize the temperature to control the watering cycle in an isolated area based on a soil moisture probe reporting from a specific row/lighting panel.

The Clarity ACS solution has been specifically designed for the grow room/greenhouse / vertical and horizontal farming grow operations based on input and feedback from industry experts and leaders in the field.

The sensors that have been selected all work seamlessly together to capture various data points about the environment and micro-environmental parameters in and around the operation.

Accessing the data collected every 5 minutes by the solution can be displayed using several connected devices including smartphones, tablets, and desktop computers.

It is here that you can interact with the data captured and analyze the information as it is being collected in the operation.

Data can be easily exported, and data access can be limited to local operational managers, regional managers corporate operational support, or collected by your IT department into your database using the Clarity Web-based API.

This API can be easily added to pull data from our database to yours on a scheduled basis.

The Clarity ACS solution has been designed with ease of installation in mind. Installation is simple and can sometimes be installed in less than one day per location.

The Clarity ACS solution provides access to the Clarity IOT Software-As-A-Service (SaaS) platform which can capture, analyze, integrate, generate and optimize key performance indicator (KPI) data that can be used to manage the operation. As time progresses and as more data is collected, the historical data is cross-referenced, and trends immediately begin to emerge. These KPI data reports can be programmed to produce a daily/weekly/monthly report depending on the client’s needs.

This operation database is constantly updated by the sensor data that is continuously collected and generated in your operation providing key insights into the organization either at the grow room level, the facility level, the regional level, or the overall corporate level.

Having this data in an easily accessible web portal (fully accessible by your IT resource(s) ) that can be shared and the ability to compare one grow facility to another or one region to another is the key to success and allows the organization to achieve consistency and growth in the operation that was never once thought possible before.

The remainder of this white paper will look at the Clarity ACS solution in more detail, explaining the starter kit contents as well as outlining the benefits and ROI that will be achieved within the first six months of implementing our solution.

Overall Solution Components

The solution outlined in this white paper is based on a Total Controlled Feedback Loop that is based on 5 key sensor readings generated by the system including:

PPFD Wavelength

CO2

Temperature

Humidity

The solution reads all sensors in the facility at a 5 minutes interval and sends the data captured to the Clarity Cloud where the proprietary algorithms are used to process and maintain the system. Based on the data captured, the system can generate alarms and notifications allowing the facility staff to address any operational parameters that need to be adjusted.

The basic components that make up the system include the following items:

1. Clarity IoT Cloud Service and Control

The Clarity Cloud is the “operating system” behind the automated grow system and contains the grow rules you can set up for your facility. All data generated by the system and all parameters that can be tuned in the system can be accessed using an Internet Web browser from various internet-enabled devices including mobile phones, tablets, and microcomputers. More details concerning the Clarity IOT Cloud and services can be found later on in this white paper.

2. Proprietary Sun Spectrum Algorithm for Wavelength Control

(Localized and Zones Time, PPFD, Co2, Temperature, and Humidity)

All customers who use the solution outlined in this paper will have access to powerful Sun Spectrum Algorithms for Wavelength Control. These light formulas can be used to help lower energy costs as well as improve production yields, product appearance, and plant vitality. Please see the Sun Spectrum section later on in this paper.

3. Clarity Gateway & Controller

The Clarity Gateway is the main data collector used in the overall solution and whose main purpose is to receive the data transmitted from each sensor installed in the facility. The Clarity Gateway’s main function is to transmit the data collected from the sensor to the Clarity Cloud. This is the only component of the solution that is connected to the Internet and all data transmitted is log chained and encrypted using sophisticated encryption algorithms. The Gateway can be connected to the Internet using a computer ethernet cable or can be connected using WIFI. For smaller facilities, 1 Gateway is typically required. For larger facilities, more Gateways can be added which is determined during the site survey process.

4. Clarity PPFD Nodes

The Clarity PPFD Node is used to measure the PAR (Photosynthetic Active Radiation) and the PPFD (Photosynthetic Photon Flux Density) available to the plant. This sensor is installed near the plants and has a radius detection of 3 feet. Additional Details on this sensor can be found later in this paper.

5. Sun Spectrum Panel

The Sun Spectrum Technologies SUN T-1 Light Emitter Panel is used to generate the proper lighting conditions for the specific plant being used. This Low Energy LED lighting panel is located near the plants and the light being emitted can be controlled automatically by the system to mimic the Sun. Please see the Sun Spectrum section later on in this document.

6. Artesyn Power Supply

The Artesyn Power Supply is used to power the Sun Spectrum SUN T-1 Light Emitter Panel. It controls the power going to the panel which in turn determines the various Red, Blue and Green light and intensity to be transmitted. More details can be found in the Artesyn Power Supply section later on in this document.

CLARITY IOT PARTNERS

The ability to build solutions with commercially available products and the ability to seamlessly integrate these third-party components into the overall solution is a key aspect of the Clarity IoT Solution. Our team of engineers has the technical know-how to integrate virtually any serial or internet-connected sensor into the solution and our experts are continually scanning the marketplace looking for forward-thinking and advanced products that can be integrated into the overall solution.

The solution described in this paper is made up of products and hardware components from multiple key third-party companies including:

ARTESYN

Artseyn is a global leader in the design and manufacture of highly reliable power conversion solutions for a wide range of industries including communications, computing, healthcare, server storage, and industrial. The Artesyn technology is primarily being used in this solution to power and control the light Sun Spectrum emitting panels controlled automatically using the Clarity IoT Cloud-based software.

Extreme Microbial Technologies

Extreme Microbial Technologies core technologies are designed to duplicate Nature’s purification processes in indoor spaces of all sizes – homes, offices, food processing facilities, grow operations, manufacturing facilities, schools, restaurants, casinos, and more. The Puradigm® GROW™ has been designed and engineered for greenhouse and indoor grow environments where Puradigm Technology is needed to reduce mold and bacteria in the air and surfaces.

Sun Spectrum Technologies

Sun Spectrum is a developer of innovative LED lighting products that offer an integrated growing system for Controlled Environment Agricultural (CEA) facilities consisting of the best, tunable light emitter that is easily adjustable throughout the entire growing cycle to almost any spectrum between 380 – 780 nm. Since these panels use LED technology, the energy costs to power them are significantly less than conventional lighting systems which generate a lot of heat.